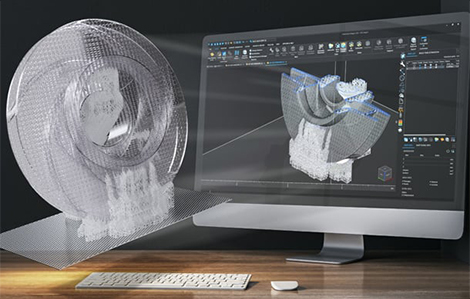

Our skilled development team evaluates the provided drawings and prepares in-house 3D casting models, ensuring compliance with achievable investment casting tolerances as per National and International standards. These 3D models are shared with the buyer for approval. Once approved, we create tool designs in-house and coordinate with our mold makers for manufacturing.

Our skilled development team evaluates the provided drawings and prepares in-house 3D casting models, ensuring compliance with achievable investment casting tolerances as per National and International standards. These 3D models are shared with the buyer for approval. Once approved, we create tool designs in-house and coordinate with our mold makers for manufacturing.

After cleaning and finishing the pattern, the assembly is prepared using a runner and riser made from wax by a wax extrusion press. The wax patterns are attached to a central wax bar, known as a sprue, forming a cluster or assembly tree.

The shell-building process involves dipping the assembly into a ceramic slurry, followed by a fine sand coating. This cycle is repeated multiple times, with up to eight layers applied, depending on the part's shape and weight, ensuring durability and precision.

We have an advanced in-house Auto-Clave facility that enhances the efficiency and precision of our investment casting process. The Auto-Clave is essential for effectively removing wax from ceramic shells, ensuring minimal residue and creating high-quality molds

This facility allows us to achieve greater dimensional accuracy, smoother surface finishes, and consistent results in our cast components. By maintaining strict temperature and pressure control, our Auto-Clave ensures that each mold meets industry standards, resulting in superior-quality castings tailored to the specific needs of our clients.

We have an advanced in-house investment casting lab equipped to carry out the entire casting process with precision and efficiency. Our investment casting process begins with creating a detailed wax pattern of the desired component using precision molds. This wax pattern is then coated with multiple layers of ceramic slurry to form a durable shell.

An Induction Furnace melts the metal to the desired temperature. In the traditional lost wax casting process, the preheated ceramic shell (up to 1000°C) is filled with molten metal using gravity pouring. As the metal cools, the parts, gates, sprue, and pouring cup fuse into a single solid casting. The shell and melt temperatures are adjusted based on the specific alloy requirements.

After the metal has cooled and solidified, the ceramic shell is removed using a knocking hammer and sandblasting, revealing the finished casting.

The parts are carefully separated from the central sprue using high-speed cutting wheels or gas cutters, followed by extrusion welding rods for precise finishing.

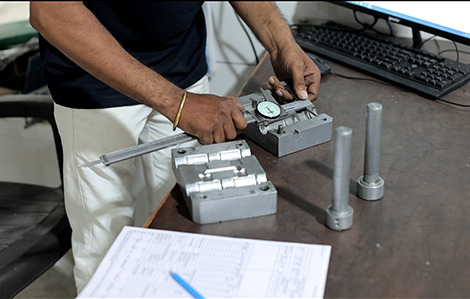

In the casting process, 50% dimensional inspection and 100% visual inspection are carried out as per customer requirements. Finally, the castings undergo thorough dimensional and visual checks, are packed according to specifications, and dispatched. Prior to dispatch, necessary tests such as heat treatment, Dye Penetrant Test, Magnetic Particle Test, and Radiography Test are conducted based on customer requirements.

After minor finishing operations, the metal castings, identical to the original wax patterns, are prepared and ready for shipment to the customer.